Sputter Deposition: Unleashing the Power of Thin Film Technology in Semiconductor Manufacturing

: The Epitome of Precision and Innovation

In the realm of semiconductor manufacturing, innovation reigns supreme. Sputter deposition stands as a testament to this relentless pursuit of excellence, propelling the industry forward with its unparalleled ability to create thin films with remarkable precision and control. This groundbreaking technique has revolutionized the production of electronic devices, paving the way for the miniaturization and enhanced performance that define modern technology.

A Journey into the Realm of Sputter Deposition

Sputter deposition is a physical vapor deposition (PVD) process that involves bombarding a target material with high-energy ions, dislodging atoms and depositing them onto a substrate. This method offers exceptional control over film thickness, composition, and microstructure, enabling the creation of custom-tailored materials for a wide range of applications.

4.5 out of 5

| Language | : | English |

| File size | : | 8749 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Print length | : | 419 pages |

| X-Ray for textbooks | : | Enabled |

The target, composed of the desired material, is placed opposite the substrate in a vacuum chamber. An inert gas, typically argon, is then introduced into the chamber and ionized by an electrical field. The ions are accelerated towards the target, colliding with its surface atoms and causing them to be ejected. These dislodged atoms travel across the chamber and condense onto the substrate, forming a thin film.

Unveiling the Wide-Ranging Applications of Sputter Deposition

The versatility of sputter deposition extends to a plethora of applications across diverse industries, including:

Semiconductor Manufacturing

* Creation of metal interconnects and barriers * Deposition of dielectric layers for capacitors and insulators * Fabrication of magnetic films for magnetic sensors

Solar Cell Production

* Deposition of transparent conductive oxide (TCO) layers * Creation of anti-reflection coatings

Optical Coatings

* Production of mirrors, filters, and anti-reflective lenses

Hard Coatings

* Deposition of wear-resistant coatings for tools and components

Delving into the Intricacies of Sputter Deposition Techniques

Various sputter deposition techniques have emerged, each catering to specific requirements:

DC Sputtering

* Utilizes a direct current (DC) power supply to generate ions * Suitable for depositing conductive materials

RF Sputtering

* Employs a radio frequency (RF) power supply, allowing for the deposition of insulating materials

Magnetron Sputtering

* Incorporates magnets to confine and enhance the plasma, achieving higher deposition rates and improved film quality

Pulsed DC Sputtering

* Modulates the power supply, enabling better control over film properties and reduced defects

Unveiling the Advantages of Sputter Deposition

Sputter deposition offers a multitude of benefits that set it apart from other thin film deposition techniques:

High-Quality Films

* Excellent adhesion, uniformity, and crystallinity * Tailorable properties, such as electrical conductivity, magnetic permeability, and optical absorption

Versatility

* Deposition of a wide range of materials, including metals, insulators, and semiconductors * Compatibility with various substrate materials

Control and Precision

* Precise control over film thickness, composition, and microstructure * Repeatability and uniformity across large deposition areas

Environmental Friendliness

* Minimal waste generation compared to chemical vapor deposition (CVD) techniques

Tapping into the Expertise: ISSN 26 - A Comprehensive Guide to Sputter Deposition

"Sputter Deposition To Semiconductor Manufacturing" (ISSN 26) is an authoritative and comprehensive resource that delves into the groundbreaking world of sputter deposition. This essential publication provides invaluable insights into:

Fundamental Principles

* Theories and mechanisms underlying sputter deposition * Characterization techniques for thin films

Advanced Techniques

* Innovative methods, such as reactive sputtering and ion beam sputtering * Emerging applications in emerging industries

Industry Best Practices

* Practical guidelines for maximizing deposition efficiency * Troubleshooting and quality control measures

: Empowering Innovation with Sputter Deposition

Sputter deposition has revolutionized the field of semiconductor manufacturing, enabling the creation of ultra-thin films with unparalleled precision and control. Its versatility extends to a multitude of applications, ranging from microelectronics to solar cells and optical coatings. As the industry continues to push the boundaries of technology, sputter deposition will undoubtedly remain a cornerstone of innovation, empowering the development of next-generation devices and shaping the future of electronics.

For those seeking to delve deeper into the intricacies of this remarkable technique, "Sputter Deposition To Semiconductor Manufacturing" (ISSN 26) stands as an indispensable guide, offering a comprehensive exploration of its principles, applications, and industry best practices.

4.5 out of 5

| Language | : | English |

| File size | : | 8749 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Print length | : | 419 pages |

| X-Ray for textbooks | : | Enabled |

Do you want to contribute by writing guest posts on this blog?

Please contact us and send us a resume of previous articles that you have written.

Book

Book Novel

Novel Page

Page Chapter

Chapter Text

Text Story

Story Genre

Genre Reader

Reader Library

Library Paperback

Paperback E-book

E-book Magazine

Magazine Newspaper

Newspaper Paragraph

Paragraph Sentence

Sentence Bookmark

Bookmark Shelf

Shelf Glossary

Glossary Bibliography

Bibliography Foreword

Foreword Preface

Preface Synopsis

Synopsis Annotation

Annotation Footnote

Footnote Manuscript

Manuscript Scroll

Scroll Codex

Codex Tome

Tome Bestseller

Bestseller Classics

Classics Library card

Library card Narrative

Narrative Biography

Biography Autobiography

Autobiography Memoir

Memoir Reference

Reference Encyclopedia

Encyclopedia Wesley L Fox

Wesley L Fox Rose Parr

Rose Parr Vikas Bhushan

Vikas Bhushan Shawn Dubravac

Shawn Dubravac Simon Grabowsky

Simon Grabowsky Stan Phelps

Stan Phelps Sandra Steingraber

Sandra Steingraber Scott Boyter

Scott Boyter Sanjeeb Behera

Sanjeeb Behera Robert Bancalari

Robert Bancalari Stephen C W Graves

Stephen C W Graves William Dietrich

William Dietrich Roby Jose Ciju

Roby Jose Ciju Robert Newell

Robert Newell Ron Clements

Ron Clements Scott Lowe

Scott Lowe Ulla Schmid

Ulla Schmid S Hayashi

S Hayashi Robert Sherrick Brumbaugh

Robert Sherrick Brumbaugh Robert Merrihew Adams

Robert Merrihew Adams

Light bulbAdvertise smarter! Our strategic ad space ensures maximum exposure. Reserve your spot today!

Philip BellIranian Women and Gender in the Iran-Iraq War: Gender, Culture, and Politics...

Philip BellIranian Women and Gender in the Iran-Iraq War: Gender, Culture, and Politics...

Israel BellUnlock the Realm of Transcendence: A Comprehensive Guide to Transcendentalism...

Israel BellUnlock the Realm of Transcendence: A Comprehensive Guide to Transcendentalism... Leon FosterFollow ·5.6k

Leon FosterFollow ·5.6k Rob FosterFollow ·2k

Rob FosterFollow ·2k Dylan HayesFollow ·3.1k

Dylan HayesFollow ·3.1k Colt SimmonsFollow ·4.2k

Colt SimmonsFollow ·4.2k Jean BlairFollow ·18.7k

Jean BlairFollow ·18.7k Javier BellFollow ·16.2k

Javier BellFollow ·16.2k Virginia WoolfFollow ·2.7k

Virginia WoolfFollow ·2.7k DeShawn PowellFollow ·4.1k

DeShawn PowellFollow ·4.1k

Colt Simmons

Colt SimmonsLarge Collieries Iron Mines Stone Iron And Tinplate...

Step back in time and witness...

Zachary Cox

Zachary CoxUnlocking the Secrets of Woody Plants: An In-Depth...

: Embark on a captivating journey into the...

Yasunari Kawabata

Yasunari KawabataIntroducing 'Librarian Guide: 3rd Edition' – The Ultimate...

In the dynamic and ever-evolving...

Jerome Blair

Jerome BlairEvading Honesty: A Masterful Exploration of Deceit and...

Prepare to be captivated...

Timothy Ward

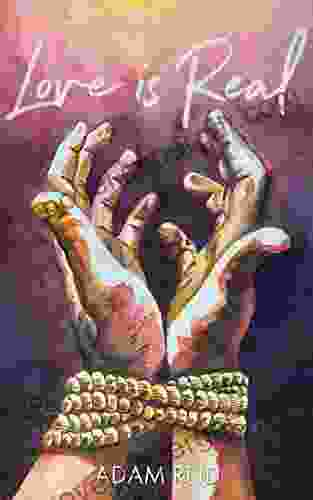

Timothy WardLove Is Real: A Novel of Love, Loss, and the Enduring...

Prepare to embark on a...

4.5 out of 5

| Language | : | English |

| File size | : | 8749 KB |

| Text-to-Speech | : | Enabled |

| Screen Reader | : | Supported |

| Print length | : | 419 pages |

| X-Ray for textbooks | : | Enabled |